| Model | MR8-300R |

|---|---|

| Function | ·Pouch Fill/Sealing Machine ·Spout Pouch Packaging Machine |

| Capacity (PPM) | 30~40bags/min(the speed depends on type of products) 25~30bags/min (for zipper pouch) |

| Pouch Size | Width(mm): 200~300 Length(mm): 100~350 |

| Filling Volume | 10-2500g(Depending on type of products) |

| Filling Product | ·Solid ·Liquid Thick liquid Powders Grains |

| Package Accuracy | Error≤±1 |

| Total power | 3.5KW(220V/380V,3PH,50HZ) |

| Demension | 2460*1830*1460mm(L*W*H) |

| Weight | 1480KGS |

| Compress air requirement | ≥0.8m³/min supply by user |

| Application | puffed food, candy, pickle, seasoning, pesticide and fertilizer, dried bean curd (solid, liquid, thick liquid, powders, grains) |

| Pouch type | stand up pouches, zipper bags, paper bags, four sides sealed bag... |

| Features | 8 stations; wash down; retortable; easy to operate |

Application

Block: chocolate, candies, cereal, biscuits, cakes, puffed food, etc.

Granule: nuts, capsules, seeds, feeds, pesticides, fertilizers, etc.

Powder: seasoning, milk powder, washing powder, fine sugar,etc.

Liquid/paste: detergent, juice, beverage, ketchup, jam,etc.

Pickles: carrots, etc.

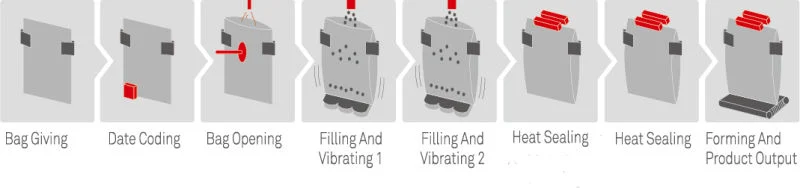

Work Process

bag giving→date coding →bag opening →filling and vibrating 1→filling and vibrating2→heat sealing 1→heat sealing 2→forming and output

Pouch Type

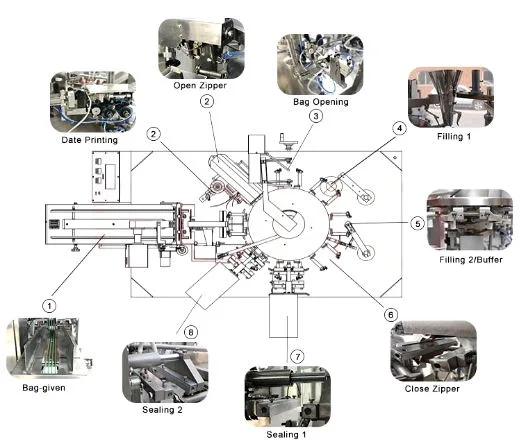

Standard Equipment Part

| 1. Date printer | 6. Magnetic valve |

| 2. PLC control system | 7. Temperature controller |

| 3. Pouch opening devices | 8. Vacuum pump |

| 4. Vibrator device | 9. Frequency convertor |

| 5. Cylinder | 10. Output system |

Features and Characteristics

1.Suitable pouches: All kinds of size premade pouches.

2.Easy to operate: PLC controller, HMI system, fault indication on the touch screen.

3.Easy to adjust: All working process in one station, more easily adjusting.

4.Frequency control: Speed can be adjusted by frequency conversion within the range.

5.High Automation: Unmanned in weighing and packing process, machine alarm automatically when failure.

Associated Equipment