Item Introduction

Function and characteristics

1.Easy to operate

2.Automatic checking

3.Safty device:

4.The width of the bags could be adjusted by electrical motor.

5.It matches with the glass safety door.

6.The packing materials loss low,

7.With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

8.The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

Technical Features:

| Model No. | TOPY-MDPT1 | TOPY-MDPT2 |

| Bag Width | 70-280mm | 70-280mm |

| Bag Length | 80-320mm | 80-440mm |

| Bag Type | Stand-up bag, pillow bag | Stand-up bag, pillow bag |

| Power Supply | 220V, 50HZ | 220V, 50HZ |

| Air Consumption | 7.0 CFM@80 PSI | 7.0 CFM@80 PSI |

| Pneumatic Parts | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan | PIAB Vacuum Generator, Pneumatics component Airtac from Taiwan |

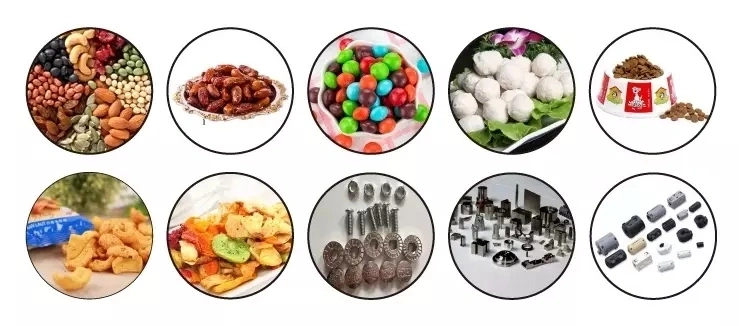

Doypack machine is suitable for all kinds of the premade bags, such as pillow bag, 3-side, 4-side and 8-side quad seal bags (box pouch), kraft bags and spout bags and so on

| 10 heads scale(weigher) | ||

| Max. Cap.(g) | 10-1000g |

| Weighing Accuracy(g) | ±0.1-1.5g | |

| Max. Weighing Speed | 65PPM | |

| Hopper Volume | 1.6L | |

| Control Panel | 9.7" Touch Screen | |

| Options | Dimple Plate/Timing Hopper/Printer/Rotary Top Cone | |

| Driving System | Step Motor | |

| Power Requirements | 220V / 1000W / 50/60HZ / 10A | |

| Packing Dimension(mm) | 1620(L)x1100(W)x1100(H) | |

| Gross WGT | 450KG | |

| Z-type bucket conveyor | ||

| Model | TOPY-BE1 |

| Bucket volume | 1.8L | |

| Materical | SS 304 and food grade PP | |

| Power | 750W | |

| Production capacity | 4-6.5 m³/hour | |

| infeed length | 863 mm | |

| Outlet height | 3296 mm | |

| Overall size | 2065(L)×1406(W)×1140(H)mm | |

| Platform for scale(weigher) | ||

| Model | TOPY-18 |

| Maximum Loading Weight | 2T-3T | |

| Equipment Size | 1800mm*1800mm*2000mm | |

| Material | SS 304 | |

| Net Weight | 350kg | |

| Take away conveyor | ||

| Model | TOPY-TC1 |

| Convey speed | 30M/min | |

| Material | SS 304 | |

| Belt | Food grade polypropylene(PP) | |

| Voltage | Single-phase AC220V,50HZ | |

| Power | 180W | |

| Packing size | 1600mm(L)*520mm(W)*1000mm(H) | |

Doypack machine device detailed picture

- Certification: our electrical device have the highest CSA certification

- Gusset device: For making gusseted bag or block bottom bag.

- Auto tracking device: For automatically regulation film position.

- Date printer: To print code, one line or two lines, maximum 11 letters per one line.

- Air expeller: Expel air from the bag to be finished.

- Hole pouch device: Pouch hole to handle bag.

- Bag supporter: For big weight.

Company Information

TOP Y MACHINERY Co., LTD was founded in October 2011 in Lunjiao Town, Foshan City, and then we moved to Qide Industrial Park, Beijiao Town. We are integrated company with R&D, building, marketing and providing after-sale services backup.

1, VP vertical forming filling sealing machine for roll of film

2, Sachet packing machine for small bag

3, Powder packaging systems

4, Granule packaging systems

5, Liquid packaging systems

And turnkey material handling, weighing, packaging and inspecting solutions for granule, powder and liquid.

Certification

Good Feedback

Shipping and Packing

Shipping

- 3-15 working days since payment receipt(based on actual quantity)

- Tracking No. Will be sent to you after delivery. And you will get every important shipping status by email.

Packing

plywood cases packed

After Service

*Pre-Sales Service

1.Inquiry and consulting support, professional packing solution for free.

2.Machine videos for your reference.

3.Sample testing support.

4. View our Factory.

*After-sale Service

1. Manules / Videos of machine installation, adjusting, setting, maintenance are available for you.

2. If any problems happen and you can not find out the solutions, Telecom or Online face to face communication available 24 hours.

3. Engineers & technicians are available to send to your countries for services if you agree to pay the expenditure.

4. The machine will have a 1-year warranty for the machine,2 years warranty for the electric part. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one for you. The warranty will begin after the machine send out we received the B/L.

FAQ

Q1. What products do you want to pack? Solid, granule, flake, powder or liquid?

A1. For liquid we advise piston or motor pump, for powders we are advise auger filler or volumetric cup filler, for solid, flake and granules we advise multihead weigher, linear weigher or volumetric cup filler.

Q2. What are the bag sizes and target weight in each pack?

A2. For VFFS packing machine the minimum film width we work on is 120mm, the maximum film width we work on is 1200mm. For doypack machine the bag width working on is minimum 70mm and maximum bad width is 450mm.

Q3. Does your company work on OEM?

A3. Yes, we have a professional design and technical team to do the customization.

Q4. What's the delivery time after the order is placed?

A4. We arrange the shipment in 30-35days for the standard machine after receive 30% deposit.

Q5. How about the warranty?

A5. The warranty is two years and we provide lifelong maintenance.

Q6. What can you provide after service?

A6. We provide machine running video, industrial manual in English, spare parts and tools for installation. Also our engineers are available to clients' factory and technical training.